The Pharmaceutical Isolator Market: Growth, Trends, and Analysis (2024)

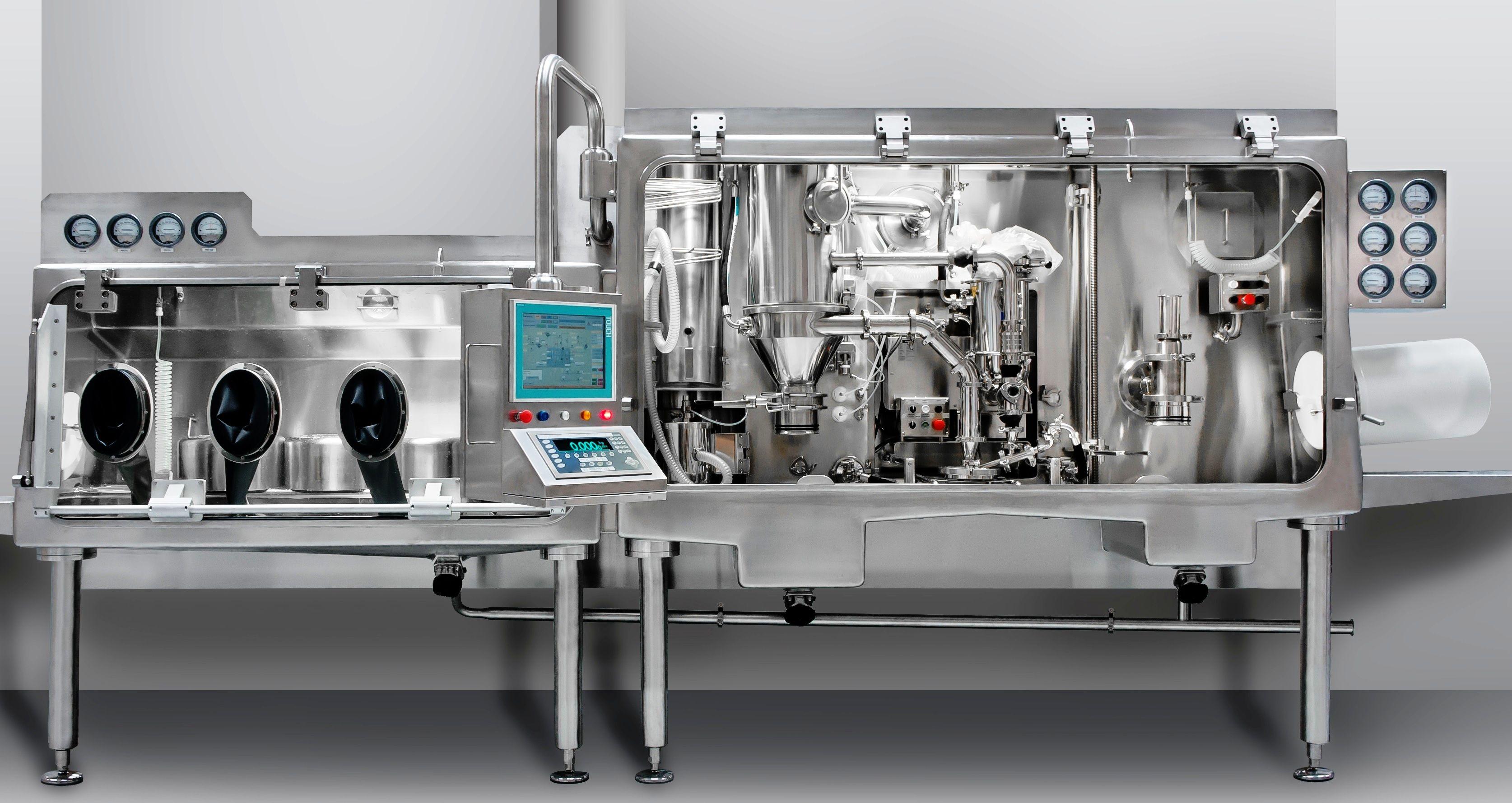

The pharmaceutical isolator market plays a critical role in ensuring the safe and efficient production of pharmaceuticals and biologics. These enclosed workstations, also known as aseptic isolators, create a barrier between the product and the surrounding environment, preventing contamination and protecting personnel from exposure to potent drugs. This comprehensive guide explores the current state of the pharmaceutical isolator market, analyzing its size, share, trends, and future prospects.

Pharmaceutical Isolator Market Size: A Booming Industry

The pharmaceutical isolator market size is experiencing significant growth, driven by several key factors. Market research reports indicate a promising future:

- Market Research Future estimates the global Pharmaceutical Isolator Market Size at USD 7.16 Billion in 2022. The Pharmaceutical Isolator market is projected to grow from USD 7.84 Billion in 2023 to USD 16.29 Billion by 2032, exhibiting a compound annual growth rate (CAGR) of 9.57% during the forecast period (2023 – 2032).

These figures highlight the considerable growth potential of the pharmaceutical isolator market.

Pharmaceutical Isolator Market Share: Key Players and Segmentation

The pharmaceutical isolator market comprises various segments and prominent players. Here's a breakdown to understand market share distribution:

- Product Segmentation: This segment categorizes the market based on the product types used for isolation. Key product categories include:

- Sterility Test Isolators: Used for aseptic testing of pharmaceutical products.

- Process Isolators: Employed for aseptic filling, handling, and processing of pharmaceutical drugs and biologics.

- Decontamination Pass Boxes: Facilitate the transfer of materials into and out of the isolator while maintaining aseptic conditions.

- Technology Segmentation: This segment focuses on the different technologies employed in isolators. Common technologies include:

- Negative Pressure Isolators: Maintain a lower pressure inside the isolator compared to the surrounding environment, minimizing the risk of contamination ingress.

- Positive Pressure Isolators: Employ a higher pressure inside the isolator, offering enhanced product protection from external contamination.

- Transfer Isolators: Smaller isolators used for transferring materials between different isolator units or cleanroom environments.

- End-User Segmentation: This segment identifies the primary users of pharmaceutical isolator solutions. Major end-user categories include:

- Hospitals and Clinics: Utilize isolators for aseptic compounding of drugs within hospital pharmacies.

- Pharmaceutical Manufacturing Companies: Implement isolators for aseptic processing and filling of pharmaceutical products.

- Contract Manufacturing Organizations (CMOs): Employ isolators to meet strict aseptic requirements for contract manufacturing of pharmaceuticals.

Leading players in the pharmaceutical isolator market include established names like Abbott Laboratories, Thermo Fisher Scientific, Getinge AB, BakerCorp, and Plantech HoldingCorp, among others. These companies are constantly innovating and developing advanced isolator technologies to enhance efficiency, safety, and operator comfort.

Pharmaceutical Isolator Market Trends: Shaping the Future

Several key pharmaceutical isolator market trends are shaping the future of the industry:

- Rising Demand for Biologics: The growing prevalence of chronic diseases and the increasing development and production of complex biologics is a significant driver of market growth. Biologic drugs often require stricter aseptic control measures, making isolators a preferred choice.

- Focus on Operator Safety: Ensuring the safety of personnel handling potent drugs is a top priority. Pharmaceutical isolators offer a high degree of containment, minimizing operator exposure to these hazardous materials.

- Technological Advancements: Technological advancements are constantly improving pharmaceutical isolator solutions. Trends include:

- Integration with Automation Systems: Isolators are increasingly being integrated with automated process equipment, streamlining workflows and enhancing production efficiency.

- Remote Monitoring and Data Management: Advanced isolators offer functionalities like real-time monitoring and data collection, facilitating improved process control and data-driven decision making.

- Focus on Sustainability: Manufacturers are developing energy-efficient isolator systems to address growing concerns about environmental sustainability within the pharmaceutical industry.

Pharmaceutical Isolator Market Analysis: Opportunities and Challenges

While the pharmaceutical isolator market analysis presents promising opportunities, there are also challenges to consider:

- High Initial Investment Costs: The initial investment cost of purchasing and installing a pharmaceutical isolator can be substantial. This can be a barrier for some companies, particularly small and medium-sized enterprises.

For more information visit at MarketResearchFuture

Other Trending Reports