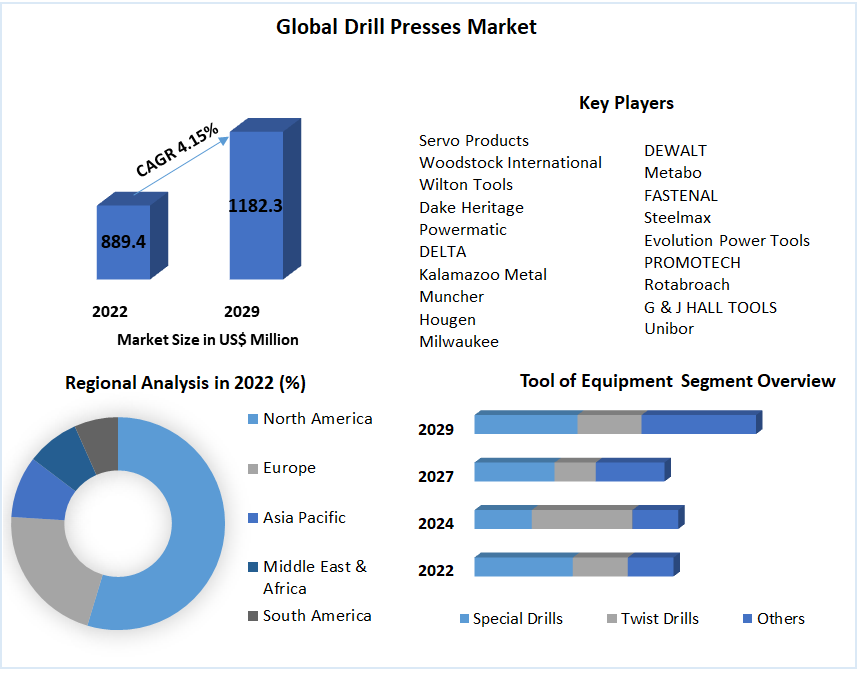

Drill Press Market reached a value of US $ 889.4 Mn. in 2022. Global Drill Presses Market size is estimated to grow at a CAGR of 4.15%.

Market Size

- 2023 Estimated Value: USD 1.8 Billion

- 2025 Projection: USD 2.1 Billion

- 2030 Forecast: USD 2.9 Billion

- Compound Annual Growth Rate (CAGR): ~6.0% from 2025 to 2030

Overview

Drill presses are stationary machinery designed for precise drilling and machining tasks across workshops, factories, and PhD-grade research environments. Ranging from lightweight benchtop models to heavy-duty floor-standing types, these tools deliver high power, speed control, and repeatability. The market is expanding due to rising demand in automotive, aerospace, metal fabrication, woodworking, and electronics industries. The emergence of CNC integration and smart connectivity is reshaping drill presses into integral parts of Industry 4.0-enabled production lines.

To Know More About This Report Request A Free Sample Copy https://www.maximizemarketresearch.com/request-sample/77942/

Market Growth Drivers & Opportunities

Key Drivers

- Precision-production Trends

Industries like automotive, aerospace, and electronics demand high-precision drilling, driving the adoption of digitally controlled spindle speeds and advanced depth control. - Industrial Automation

Integration of drill presses with CNC systems, robotic loading, and IoT-based sensors is boosting efficiency and predictive maintenance, fueling market growth. - Infrastructure & Construction Activity

Growth in real estate and infrastructure in emerging markets increases demand for construction and fabrication tools, including floor-standing drill presses. - Enhanced Manufacturing Capabilities

Rising quantities of mid-sized and artisanal manufacturing and prototyping are expanding demand for versatile shop-floor machines with powder coating and dust collection systems.

Opportunities

- Smart CNC Bench Drills for lightweight industrial and lab applications

- Multi-function Drill Presses combining drilling, tapping, and boring

- Affordable Smart Connectivity via cloud-based monitoring for SMEs

- Aftermarket Digital Retrofit Kits enabling legacy machines to adopt monitoring and connectivity

Segmentation Analysis

By Type

- Benchtop Drill Presses: Compact units for home, woodworking, and light-metal tasks; high volume in DIY and regional workshops

- Floor-standing Drill Presses: Heavy-duty units for continuous industrial use; dominant in manufacturing plants

By Drive Type

- Mechanical Belt-Drive: Traditional system with simplicity and cost efficiency

- Direct Drive / Gear Drive: Offers stability, precision, and lower maintenance needs

- CNC / Programmable Drive: Fastest-growing category with digital control and automation

By End-Use Industry

- Metalworking & Machinery: Leading sector for precision and production

- Automotive & Aerospace: High demand for accurate and repeatable drilling

- Woodworking: Wide use in furniture, cabinetry, and DIY markets

- Electronics & Technical Equipment: PCB and enclosure drilling needs driving mini bench-drills

- Education & Research: Maker spaces, labs, and institutions require multifunctional drill presses

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

Major Manufacturers

- Bosch Power Tools

- JET (JPW Industries)

- Grizzly Industrial Inc.

- Dewalt (Stanley Black & Decker)

- ROHM Products

- JET Tools (Canada)

- Clarke International

- Lagun Engineering

- Tormach

- Rikon Power Tools

- ZOJIRUSHI & MIGHTY SEVEN (Taiwanese import brands)

- Generic OEM players catering to regional markets

These manufacturers offer a range spanning entry-level machines to CNC-ready industrial systems, with growing connectivity and digital tool integration.

Get More Info: https://www.maximizemarketresearch.com/request-sample/77942/

Regional Analysis

North America

Steady growth driven by manufacturing modernization and small-business investments. The U.S. leads in CNC retrofits and industrial shop use, supported by the Maker movement.

Europe

Mature market with stable demand from automotive, aerospace, and maker sectors. Germany, Italy, and the UK are hotspots for precision floor-standing drills and retrofitting.

Asia-Pacific

Fastest-growing region, powered by rapid industrialization in China, India, Southeast Asia, and Latin American manufacturing centers. OEMs are establishing local production and sales networks.

Latin America & Middle East/Africa

Emerging demand linked to infrastructure build-out and mining operations. Regional workshops are upgrading basic drills with sturdier and smarter press models.

COVID‑19 Impact Analysis

The pandemic temporarily disrupted supply chains and slowed production. However, the shift to remote work and at-home projects led to a significant boom in benchtop drill demand. As industrial supply chains stabilized, factory and retrofit projects resumed, with increased funding toward smart manufacturing and tool automation.

Commutator Analysis

Drill press performance and versatility stem from these key components:

- Adjustable Spindle Assemblies for depth precision

- Variable Speed Mechanisms (belt or electronic) enabling material-specific drilling

- CNC Control Units for pattern drilling, depth stops, and automated cycles

- Robust Columns and Bases ensuring stability and vibration isolation

- Safety Features including guards, emergency stops, and LED lighting

- Connectivity Options like USB, Ethernet, Wi-Fi for IIoT-enabled diagnostics and part-lifecycle tracking

These feature sets support clean finishes, repeatability, and new automation capabilities.

Key Questions Answered

- What is the expected market value by 2030?

The global drill press market is projected to reach USD 2.9 Billion. - What is the growth rate?

A ~6% CAGR is anticipated from 2025 to 2030. - Which drill types dominate?

Floor-standing models lead in industrial segments; benchtop presses dominate at-home use. CNC-enabled types are expanding fastest. - Which sectors drive the market?

Metalworking, automotive, aerospace, woodworking, electronics, and education sectors are key buyers. - What trends impact future growth?

Smart automation, connectivity, CNC retrofits, and hybrid multi-function tools are reshaping product demand.

Conclusion

The global drill press market is entering a phase of robust evolution, underpinned by smart manufacturing imperatives, automation trends, and increasing demand for precision tools. With continued market expansion to nearly USD 3 Billion by 2030, drill presses are becoming core assets not only in industrial settings but also maker workshops and educational environments. Leaders in the market are innovating through CNC upgrades, IoT tool tracking, and modular design to meet diverse user needs. As the convergence of craftsmanship and digital factory trends continues, drill presses are set to remain indispensable instruments in the global manufacturing landscape.

About Maximize Market Research:

Maximize Market Research is a global market research and consulting company specializing in data-driven insights and strategic analysis. With a team of experienced analysts and industry experts, the company provides comprehensive reports across various sectors, aiding businesses in making informed decisions and achieving sustainable growth.

Contact Us

Maximize Market Research Pvt. Ltd.

2nd Floor, Navale IT Park, Phase 3

Pune-Bangalore Highway, Narhe

Pune, Maharashtra 411041, India

📞 +91 96073 65656

✉️ sales@maximizemarketresearch.com