Industrial Hose Market to Reach USD 27.5 Billion by 2030, Supported by Infrastructure Growth and Advanced Material Trends

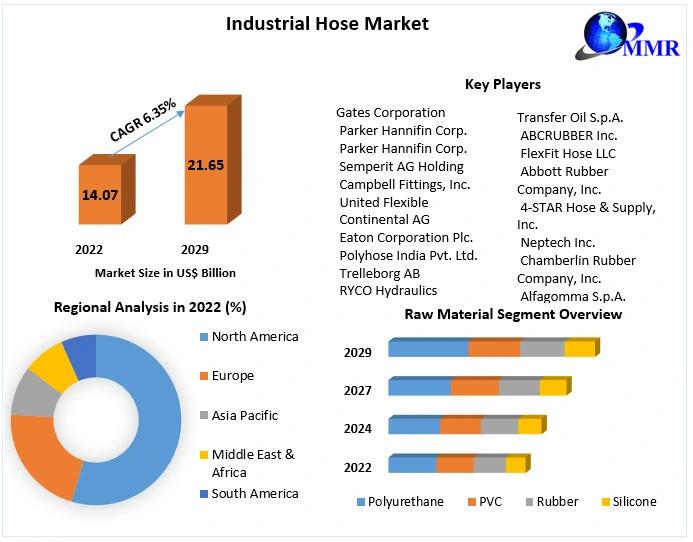

Market Size

- 2023 Market Value: USD 20.1 Billion

- 2025 Projection: USD 22.4 Billion

- 2030 Forecast: USD 27.5 Billion

- CAGR: Approximately 4.0–4.5% from 2025 to 2030

Overview

Industrial hoses are flexible, reinforced tubing designed to transfer fluids, gases, chemicals, and solids across sectors such as oil & gas, construction, agriculture, mining, manufacturing, and chemicals. Designed for pressure resistance, temperature extremes, and chemical stability, these hoses play a critical role in supply chains and operations. Market demand is rising due to global infrastructure modernization, regulatory mandates, and advances in polymer composites and smart monitoring systems aligned with Industry 4.0 standards.

To Know More About This Report Request A Free Sample Copy https://www.maximizemarketresearch.com/request-sample/23242/

Market Growth Drivers & Opportunities

Key Drivers

- Infrastructure & Construction Expansion

New highways, airports, and industrial zones drive demand for hydraulic and air hoses in heavy equipment and site services. - Oil & Gas and Energy Sector Demand

Exploration and refining require specialized hoses for high-pressure, extreme-temperature environments. - Agriculture & Mining Growth

Irrigation systems, slurry pumping, and heavy-duty mining equipment use hoses resistant to abrasion, chemicals, and pressure. - Regulatory Compliance & Safety Standards

Industrial regulations demand fire-resistant, electrostatic, and anti-static hoses to ensure worker safety and environmental protection.

Opportunities

- Development of high-temperature, lightweight composite hoses

- Integration of smart sensors for leak detection and usage monitoring

- Adoption of eco-friendly, recyclable materials

- Expansion in developing regions like Southeast Asia, Latin America, and Africa

Segmentation Analysis

By Material Type

- Rubber Hoses: Widely used – known for flexibility and strength

- PVC & Thermoplastic Hoses: Lightweight, corrosion-resistant, cost-effective

- Metal & Composite Hoses: Ideal for high-pressure, high-temperature applications

- Others: Includes PTFE, urethane, and specialty polymer hoses

By Technique

- Reinforced Hoses: Single- or multi-layer construction for heavy-duty use

- Non-Reinforced Hoses: Light-duty; suitable for low-pressure, everyday applications

By Application

- Oil & Gas – Crude handling, drilling, hydraulic systems

- Construction – Water lines, concrete pumping

- Chemicals – Corrosive fluid transfers

- Food & Beverage – Hygienic sanitary hoses

- Agriculture – Irrigation and fertilizer delivery

- Mining & Minerals – Slurry, water, and hydraulic hoses

- Manufacturing – Air, coolant, and pneumatic hoses

By Pressure Range

- Low Pressure (<150 psi)

- Medium Pressure (150–300 psi)

- High Pressure (>300 psi)

By End User Industry

- Oil & Gas, Construction, Chemicals, Manufacturing, Mining, Agriculture, Food & Beverage, Power, Healthcare, Automotive, Energy

Major Manufacturers

- Gates Corporation

- Eaton Hose Products

- Parker Hannifin

- Continental AG

- Kuriyama of America

- Bridgestone Hose Power Systems

- Trelleborg AB

- Saint-Gobain Performance Plastics

- Yokohama Rubber

- Dunlop Industrial Products

- Alfa Laval (hose lines)

- Semperit (hose division)

- Eaton (industrial products segment)

- Novaflex Group

These companies focus on advanced materials, certifications, global distribution, and smart hose technologies.

Get More Info: https://www.maximizemarketresearch.com/request-sample/23242/

Regional Analysis

North America

Dominates current market share, with strong growth in oil & gas, manufacturing, and infrastructure reinvestment. U.S. demand is driven by pipeline upgrades and heavy equipment utilization.

Europe

Steady demand led by stringent safety standards in chemical, automotive, and public infrastructure sectors. Germany, France, and Italy remain major markets.

Asia-Pacific

Fastest-growing region—China, India, and Southeast Asia fuel demand through construction booms, agricultural modernization, and energy sector expansion.

Latin America & Middle East/Africa

Emerging markets seeking infrastructure improvement and diversification of energy resources; growth backed by investments in industry and mining.

COVID‑19 Impact Analysis

The pandemic caused initial production slowdowns and supply chain disruptions, but rapid industry recovery—especially in construction and logistics—revived demand. Emphasis on automation and safe maintenance during COVID-19 has accelerated the adoption of sensor-enabled hoses and spurred reshoring initiatives in manufacturing.

Commutator Analysis

Industrial hoses incorporate specialized components that define reliability and performance:

- Reinforcement Layers: Textile, wire, or composite braids that determine pressure handling

- Cover & Liner Materials: Selected based on chemical compatibility, temperature, and abrasion

- Coupling & Fittings: Ensure secure, leak-free hose connections

- Smart Sensing Elements: Embedded sensors for pressure, temperature, and leak detection

- Protective Sleeves & Guards: Extend hose life in harsh environments

Advancements in these areas are leading to hoses that are safer, more durable, and more intelligent.

Key Questions Answered

- What is the market’s projected size by 2030?

The industrial hose market is forecast to reach USD 27.5 Billion. - What is the CAGR?

Around 4.0–4.5% from 2025 to 2030. - Which hose types are most used?

Rubber and reinforced hoses remain dominant; metal and composite hoses are growing in niche, high-pressure applications. - Which industries are the largest consumers?

Oil & gas, construction, chemicals, manufacturing, agriculture, and mining lead demand. - Which regions are propelling market growth?

Asia-Pacific is the fastest-growing region; North America and Europe hold major shares. Emerging markets are heating up.

Conclusion

The global industrial hose market is witnessing steady growth fueled by robust infrastructure development, expanding oil & gas and energy use, and advancements in materials and digital monitoring. Valued at USD 20 Billion in 2023 and expected to reach USD 27.5 Billion by 2030, the market is becoming increasingly competitive and technologically dynamic. The adoption of smart hoses and eco-friendly materials underscores the industry's shift toward sustainability and safety. With diversification of applications and geographic opportunities, industrial hose manufacturers and end-users will benefit from continued innovation and investments in the coming decade.

About Maximize Market Research:

Maximize Market Research is a global market research and consulting company specializing in data-driven insights and strategic analysis. With a team of experienced analysts and industry experts, the company provides comprehensive reports across various sectors, aiding businesses in making informed decisions and achieving sustainable growth.

Contact Us

Maximize Market Research Pvt. Ltd.

2nd Floor, Navale IT Park, Phase 3

Pune-Bangalore Highway, Narhe

Pune, Maharashtra 411041, India

📞 +91 96073 65656

✉️ sales@maximizemarketresearch.com